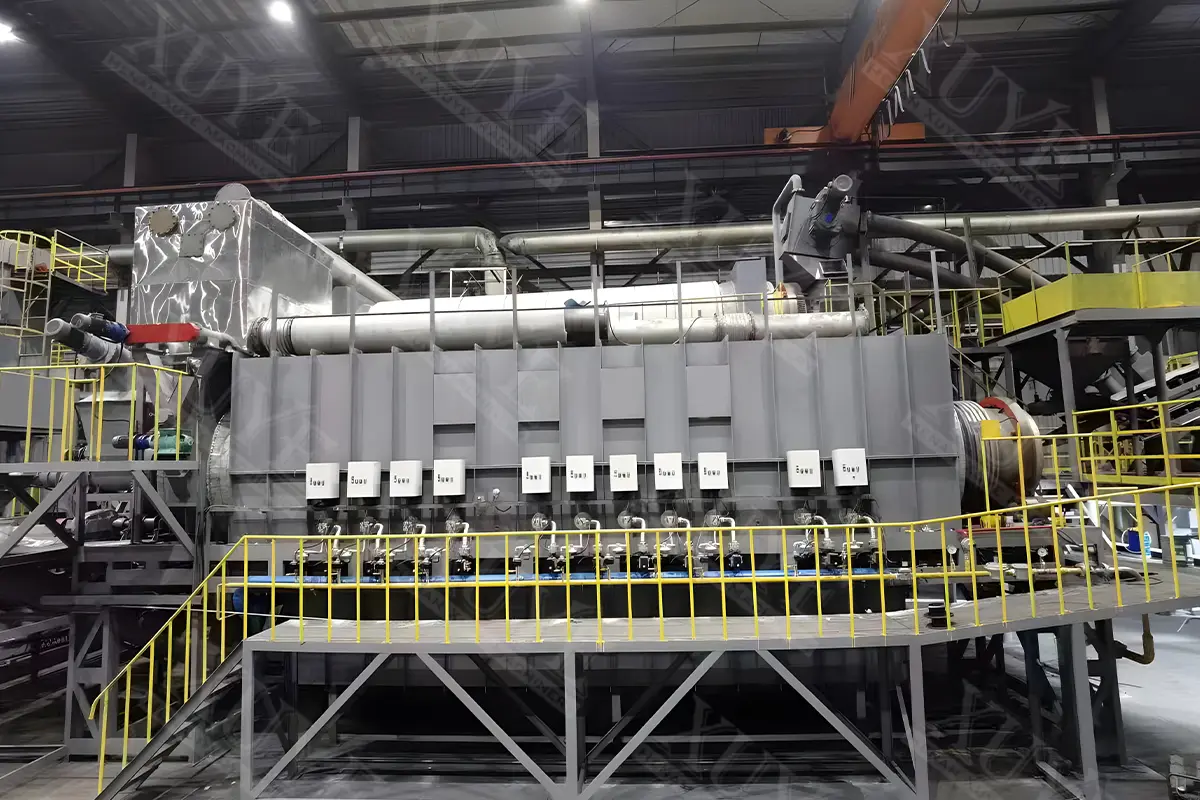

Wood biochar kiln

A wood biochar kiln is a specialized device or structure used to convert wood waste (such as branches, sawdust, or agricultural residues) into biochar through pyrolysis. Unlike traditional burning, which releases carbon dioxide (CO₂) into the atmosphere, a biochar kiln minimizes emissions by restricting oxygen, locking carbon in a stable form.

Wood biochar is a porous carbon material produced by pyrolyzing wood or other woody biomass (such as agricultural and forestry residues) under oxygen-deficient or oxygen-limited conditions. In recent years, its applications in energy, environmental remediation, agriculture, and other fields have attracted significant attention. Wood biochar, due to its carbon sequestration potential (2.5 tons of CO₂ equivalent per ton) and versatility, has become a key material in promoting carbon neutrality and a circular economy.

Working Principle of Continuous Wood Biochar Kiln

A continuous wood biochar kiln utilizes advanced carbonization technology, converting wood and other biomass materials into high-quality biochar under oxygen-deficient or oxygen-limited conditions. Unlike traditional batch carbonization furnaces, the continuous design enables 24-hour uninterrupted production, significantly improving efficiency and yield.

The entire carbonization process can be divided into three key stages:

Drying: The raw material first enters a preheating zone, where high-temperature flue gas removes moisture, preparing it for pyrolysis. This step is crucial for overall efficiency, as dry raw material requires less heat for carbonization.

Pyrolysis: The dried biomass undergoes thermal decomposition in an oxygen-deficient environment at high temperatures (typically 400-900°C). Components such as cellulose, hemicellulose, and lignin gradually decompose, producing biochar, combustible gases (such as carbon monoxide, methane, and hydrogen), and a small amount of wood vinegar as byproducts.

Cooling: The carbonized biochar is cooled by a specialized cooling system to prevent spontaneous combustion and ensure product safety and consistent quality.

Modern continuous wood biochar kilns often utilize a gas recycling system, purifying the combustible gases produced by pyrolysis and reusing them as a heating energy source. This creates a closed-loop energy cycle and significantly reduces external energy requirements. For example, some advanced models utilize a gasifier to generate gas, which is then purified and used to heat the carbonization tubes, creating a self-sufficient energy cycle.

Core Advantages of Continuous Wood Biochar Kilns

Continuous wood biochar kilns offer significant advantages over traditional carbonization methods in many areas, making them the preferred technology for modern biomass processing.

1.Excellent Environmental Performance

Xuye’s continuous wood biochar kilns are equipped with advanced flue gas purification systems that effectively remove harmful substances such as dust, tar, and wood acid generated during the carbonization process, ensuring that emissions meet strict environmental standards. Gas recirculation combustion technology prevents the direct release of combustible gases into the atmosphere, reducing both energy waste and greenhouse gas emissions.

Furthermore, this equipment utilizes “autogenous combustion”—using its own combustible gases as a power source, forming a closed-loop system. For example, after initial startup using a gasifier to generate gas, the system quickly becomes able to sustain operation solely on the carbonization gas, eliminating the need for additional fuel input. This design is both environmentally friendly and highly economical.

2.Highly Efficient Production Capacity

The continuous design enables these carbonization kilns to operate 24 hours a day, continuously feeding and discharging materials without frequent downtime, resulting in production efficiency several times higher than traditional batch kilns. The multi-layer carbonization bed structure and optimized heating method further shorten carbonization time, with some models capable of processing hundreds of kilograms of raw materials per hour.

For example, the multi-layer continuous carbonization furnace utilizes a unique layer-by-layer unloading mechanism. A motor-driven unloading rake on a central shaft rotates, allowing the raw materials to fall layer by layer from the top carbonization bed. The carbonized product is then continuously discharged from a spiral discharger at the bottom. This design ensures continuous and stable production.

3.Energy Saving and Automation

Modern continuous wood biochar kilns commonly utilize waste heat recovery technology, utilizing the heat generated by high-temperature flue gas and combustible gas combustion to preheat and dry incoming materials, significantly reducing energy consumption. The heat recycling system fully utilizes thermal energy, resulting in energy efficiency improvements of over 40% for some models compared to traditional equipment.

Another highlight is the automated control system. The application of PLC and IoT technologies enables precise monitoring and automatic adjustment of the entire carbonization process, including key parameters such as temperature control, feed rate, and gas flow. This not only ensures consistent product quality but also reduces the need for manual operation and labor intensity. A fault alarm system promptly alerts operators of abnormal conditions, ensuring safe production.

4.Excellent Product Quality

Continuous wood biochar kilns precisely control carbonization parameters (temperature, time, speed, etc.) to produce high-quality biochar with consistent quality and high carbon content. Rotating or specially designed material conveying systems ensure uniform heating of the raw materials, avoiding the uneven carbonization common with traditional methods.

Based on specific needs, operators can adjust process parameters to produce biochar products suitable for different applications. For example, biochar produced at higher temperatures (600-900°C) has a higher carbon content and higher conductivity, making it suitable for use as a soil conditioner or electronic material. Products produced at lower temperatures (400-600°C) retain more functional groups and perform better in applications such as water treatment.

Batch carbonization furnace

Continuous wood biochar kiln

The Application Value of Continuous Wood Biochar Kilns

The high-quality biochar produced by continuous wood biochar kilns has a wide range of applications, providing environmentally friendly and efficient solutions for multiple industries.

1.Agriculture and Soil Improvement

Wood biochar performs exceptionally well as a soil conditioner. Its porous structure improves soil’s ability to retain water and fertilizer, and its abundant pores provide a habitat for beneficial microorganisms.1 Studies have shown that crop yields in biochar-amended soils can increase by 20-30% while reducing fertilizer requirements. However, it should be noted that excessive use in alkaline soils may inhibit microbial activity, and it is recommended to control the addition amount to avoid significant pH fluctuations.

In terms of composting efficiency, adding approximately 10% wood biochar can extend the high-temperature period and significantly reduce greenhouse gas emissions. It also effectively reduces odor intensity. This application method can also achieve carbon negative emissions, providing a new approach for sustainable agricultural development.

2.Environmental Remediation

Wood biochar performs exceptionally well in the remediation of contaminated water and soil. Its high specific surface area (reaching over 500 m²/g upon activation) and abundant surface functional groups enable it to effectively adsorb heavy metals (such as As⁺ and Cu⁺) and organic pollutants. Specially designed composite biochars (such as Fe₃O₄@W-BC) not only adsorb pollutants but also reduce highly toxic Cr⁶⁺ to less toxic Cr⁺, achieving harmless treatment of pollutants.

In wastewater treatment, large-scale production has reduced the cost of wood biochar to approximately $0.5 per kilogram. Once saturated, it can be recycled and reused (maintaining 85% efficiency after five cycles).

3.Energy and Industrial Applications

Wood biochar can be used as a clean fuel, with a calorific value of 22.9 MJ/kg, comparable to bituminous coal. The double-layer continuous carbonization furnace system integrates biomass pyrolysis and biochar production, achieving a thermal efficiency of 30-40%, meeting strict emission standards, and producing a 30-40% biochar byproduct.

4.Carbon Sequestration and Climate Change Response

The carbon sequestration capacity of wood biochar is a significant environmental benefit. As a stable form of carbon, biochar can lock carbon in wood for hundreds or even thousands of years. Research indicates that each ton of wood biochar used can sequester approximately 2.5 tons of CO₂ equivalent. China has issued the “GB/T 44290-2024” standard, which standardizes the calculation method for the biogenic carbon content of wood and wood products, providing a technical foundation for carbon footprint accounting and carbon trading.1 This “climate-smart” material is becoming a crucial tool for countries to achieve their carbon neutrality goals.

Wood Biochar kiln technical parameter

| Modèle | XY-800 | XY-1000 | XY-1200 | XY-1500 | XY-1800 | XY-2000 |

| Nombre de couches de cylindres | Unique | Unique | Double | Double | Double | Double |

| Diamètre du cylindre | 800mm | 1000mm | 1200/700mm | 1500/900mm | 1800/1200mm | 2000/1500mm |

| Capacité | 200-300kg/h | 300-400kg/h | 450-600kg/h | 600-800kg/h | 800-1000kg/h | 1000-1200kg/h |

| Matériau du cylindre | 309S/310S/316L | 309S/310S/316L | 309S/310S/316L | 309S/310S/316L | 309S/310S/316L | 309S/310S/316L |

| Température | 500-800ºC | 500-800ºC | 500-800ºC | 500-800ºC | 500-800ºC | 500-800ºC |

| Temps de carbonisation | 20-60 minutes | 20-60 minutes | 20-60 minutes | 20-60 minutes | 20-60 minutes | 20-60 minutes |

| Taille des particules de la matière première | ≤4cm | ≤4cm | ≤4cm | ≤4cm | ≤4cm | ≤4cm |

| Méthode de chauffage | chauffage indirect | chauffage indirect | chauffage indirect | chauffage indirect | chauffage indirect | chauffage indirect |

| Mode de fonctionnement | travailler en permanence | travailler en permanence | travailler en permanence | travailler en permanence | travailler en permanence | travailler en permanence |

| Méthode de contrôle | Contrôle PLC | Contrôle PLC | Contrôle PLC | Contrôle PLC | Contrôle PLC | Contrôle PLC |

The video of wood biochar kiln

How to Choose the Right Continuous Wood Biochar Kiln

With a wide variety of continuous wood biochar kiln models on the market, users need to select the most suitable equipment based on their needs. The following are key considerations:

1.Production Capacity Requirements

The production capacity of different continuous carbonization furnace models varies significantly, ranging from tens of kilograms to nearly one ton per hour. Small equipment is suitable for startups or small-scale applications, while large continuous production lines are suitable for industrial-scale production. When choosing a suitable equipment, consider raw material availability, market demand, and investment budget.

Multi-layer continuous carbonization furnaces generally offer higher space utilization and production efficiency. For example, a patented design utilizes multiple layers of staggered semicircular carbonization beds, with a central rotating shaft driving the unloading rake to achieve continuous production. This compact design offers impressive production capacity.

2.Raw Material Adaptability

Different equipment has varying requirements for raw material type and specifications. Most continuous carbonization furnaces are suitable for processing granular raw materials under 15 mm, such as sawdust, rice hulls, and peanut shells. Some specialized models can handle larger raw materials, such as wood bar carbonization furnaces that can handle rods several centimeters in diameter.

For high-moisture raw materials, a model equipped with a pre-drying system is ideal. For example, a biomass continuous carbonization system features an integrated drying system that can process raw materials such as sawdust and wood chips with a moisture content below 30%. This design avoids the high energy consumption associated with direct carbonization of wet raw materials.

3.Environmental Compliance

A rigorous flue gas treatment system is a core feature of an environmentally friendly continuous carbonization furnace. High-quality equipment typically features multi-stage purification, including spray cooling, dust removal, and tar and wood vinegar collection, to ensure emissions meet standards. Before purchasing, it’s important to check whether the equipment’s emissions data complies with local environmental regulations.

The “autogenous combustion” design is another environmentally friendly feature. For example, some models recycle the carbonization flue gas by returning it to a purification system, converting it into combustible gas, which is then returned to the furnace for combustion, achieving virtually smokeless emissions.

3.Level of Automation

Modern continuous carbonization furnaces have varying levels of automation. Basic models may require significant manual operation, while high-end equipment features PLC control systems that automatically adjust parameters such as temperature, feed rate, and gas flow. The use of IoT technology also allows for remote monitoring and troubleshooting, significantly reducing the need for skilled operators.

For users seeking stable production and consistent product quality, choosing highly automated equipment, while requiring a higher initial investment, can reduce labor costs and production fluctuations in the long term.

Henan Xuye Machinery Equipment Co. Ltd.

Henan Xuye Machinery Equipment Co. Ltd.