Continuous biochar furnace

A continuous biochar furnace is a highly efficient carbonization device that converts carbonaceous materials (such as sawdust, rice husks, and straw) into charcoal or charcoal powder at high temperatures through dry distillation and oxygen-free carbonization. Its core principle is to control the temperature (typically 250°C to 800°C) and oxygen-deficient conditions in a sealed environment to remove moisture, pyroacetic acid, and wood tar from the raw materials, thereby increasing the carbonization rate. The equipment utilizes a continuous feed-and-discharge system, with raw materials input at one end and the finished product directly output at the other. Its highly automated operation replaces traditional intermittent kilns, significantly improving production efficiency.

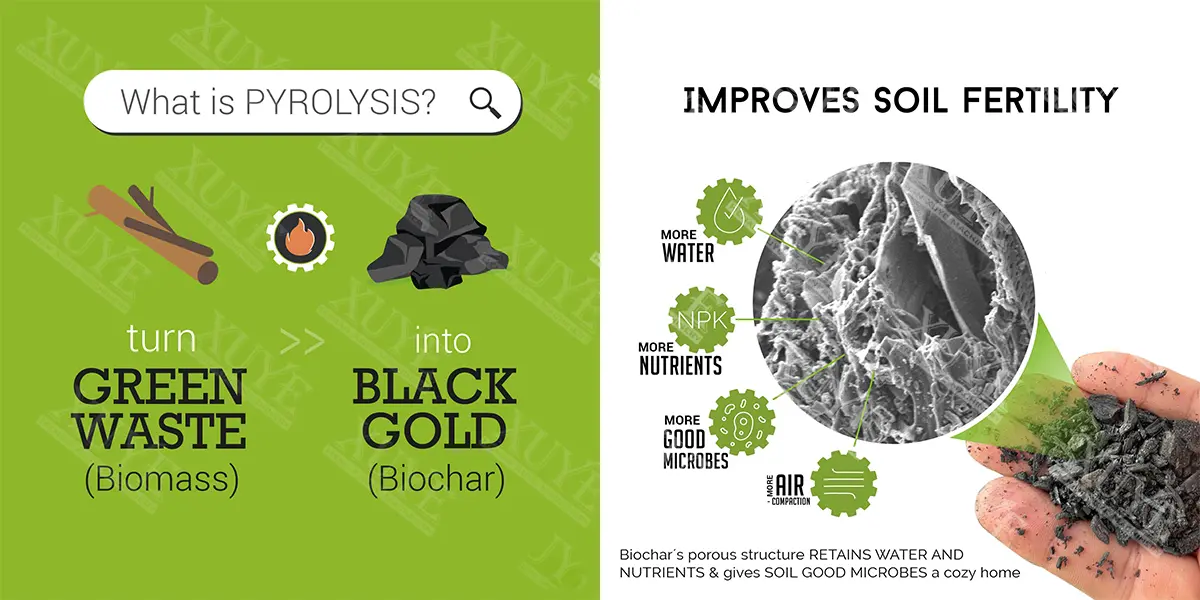

The Continuous biochar Furnace is a highly efficient, automated biomass pyrolysis system capable of continuous feeding, carbonization, and discharge under oxygen-free or low-oxygen conditions, enabling large-scale biomass waste processing. Its core principle is based on the pyrolysis reaction, which decomposes organic matter at high temperatures to produce biochar, combustible gases, and liquid byproducts. The following is a detailed explanation of its working principle:

In an oxygen-free or oxygen-limited environment, biomass (such as straw, sawdust, and sludge) undergoes chemical decomposition under heat. This decomposition occurs in three main stages:

Drying (100-200°C): Water evaporates.

Pyrolysis (200-600°C): Macromolecular organic matter (cellulose, hemicellulose, and lignin) is pyrolyzed, producing volatiles (gas and tar) and solid char.

Carbonization (600-800°C): Volatile matter is further pyrolyzed, stabilizing the char structure and increasing porosity.

Environmental Advantages and Application Scenarios of Biochar furnace

Environmental Performance: Reduced Pollution and Resource Recycling

Low Emissions: Compared to traditional incineration methods, biochar stoves process biomass through pyrolysis (rather than direct combustion), reducing the release of CO₂ and harmful gases. For example, commercial-scale pyrolysis equipment can capture syngas and bio-oil for energy, avoiding the air pollution caused by open-air burning.

Waste Resource Utilization: Biochar stoves can process organic waste such as agricultural straw, sugarcane bagasse, and peanut shells, transforming biomass that would otherwise be burned or inefficiently used in the field into biochar, energy, and soil conditioners, effectively turning waste into treasure.

Application Scenarios: Suitable for a variety of fields, from agriculture to industry

Agricultural Production: Small mobile pyrolysis stoves can directly serve farms, processing biomass on-site and returning biochar to the fields, improving soil fertility (especially in acidic soils).

Scaled Processing: Large-scale pyrolysis plants are suitable for processing bulk feedstocks such as municipal waste and paper byproducts. Through continuous production, they output biochar, syngas, and bio-oil to meet energy or material needs.

Video of biochar furnace

Biochar furnace technical parameter:

| Model | XY-800 | XY-1000 | XY-1200 | XY-1500 | XY-1800 | XY-2000 |

| Number of cylinder layers | Single | Single | Double | Double | Double | Double |

| Cylinder diameter | 800mm | 1000mm | 1200/700mm | 1500/900mm | 1800/1200mm | 2000/1500mm |

| Capacità | 200-300kg/h | 300-400kg/h | 450-600kg/h | 600-800kg/h | 800-1000kg/h | 1000-1200kg/h |

| Cylinder material | 309S/310S/316L | 309S/310S/316L | 309S/310S/316L | 309S/310S/316L | 309S/310S/316L | 309S/310S/316L |

| Temerature | 500-800ºC | 500-800ºC | 500-800ºC | 500-800ºC | 500-800ºC | 500-800ºC |

| Carbonization time | 20-60min | 20-60min | 20-60min | 20-60min | 20-60min | 20-60min |

| Raw material particle size | ≤4cm | ≤4cm | ≤4cm | ≤4cm | ≤4cm | ≤4cm |

| Heating method | indirect heating | indirect heating | indirect heating | indirect heating | indirect heating | indirect heating |

| Operation mode | continuously working | continuously working | continuously working | continuously working | continuously working | continuously working |

| Control method | PLC control | PLC control | PLC control | PLC control | PLC control | PLC control |

Henan Xuye Machinery Equipment Co., Ltd.

Henan Xuye Machinery Equipment Co., Ltd.