Core Applications and Technological Innovations of Rotary Activation Furnaces in Activated Carbon Production

Activated carbon, hailed as “industrial MSG” and “universal adsorbent,” plays an indispensable role in key fields such as water treatment, air purification, food and pharmaceuticals, chemical catalysis, and even new energy. Its remarkable adsorption capacity stems from its highly developed microporous structure and enormous specific surface area. However, converting common raw materials such as coconut shells, wood chips, or coal into high-performance activated carbon requires a series of stringent high-temperature physicochemical transformations. This process places extremely high demands on production equipment: it must ensure uniform heating of the materials to avoid excessive ablation; it must precisely control the temperature and reaction atmosphere to “sculpt” the ideal pore size distribution; and it must also meet the economic requirements of large-scale, continuous production.

Among numerous thermal equipment, the Rotary Activation Furnace/Kiln stands out with its unique design concept and excellent process adaptability, becoming the core equipment for the production of mid-to-high-end activated carbon, especially high-quality coconut shell activated carbon. Like a continuously operating “rotating workshop,” it provides a near-perfect reaction environment for the creation of activated carbon through its inclined cylinder and precise control system. This report will delve into the crucial role of the rotary activation furnace in the entire activated carbon production process, systematically elucidate its core technology from carbonization to activation, compare the advantages and disadvantages of different technical routes, and explore its technological innovation and future development under the wave of greening and intelligentization. It aims to provide practitioners and researchers in the activated carbon industry with a comprehensive and in-depth technical reference.

1.Technical Principles – Why the Rotary Activation Furnace is the Ideal Choice.

To understand the core role of the rotary activation furnace in activated carbon production, we must first explore how its unique working principle and structural design perfectly match the needs of activated carbon preparation.

(1)Basic Working Principle: Uniform Heat Transfer Through Dynamic Tumbling

The core advantage of the rotary activation furnace lies in its unique material movement and heat transfer mechanism, transforming the static batch reaction into a dynamic one.

Core Motion Mechanism: The furnace body is a slightly tilted and slowly rotating cylinder. When raw materials such as coconut shells are fed in from the higher feed end, under the combined action of gravity and cylinder wall friction, the material undergoes a complex motion: on the one hand, it is carried to a certain height and rolls down as the cylinder rotates, forming continuous tumbling along the circumference; on the other hand, due to the tilt of the cylinder, the material moves slowly towards the lower discharge end while tumbling. This “tumbling-forward” motion mode ensures that every material particle is fully and uniformly exposed to the high-temperature environment, making efficient contact with the hot gas flow or activator (such as steam). This is crucial for avoiding localized overheating and ensuring the uniformity of carbonization and activation reactions.

Complex Heat Transfer Mechanism: Heat transfer within the furnace is a complex process involving conduction, convection, and radiation. Among these, thermal radiation plays a dominant role, especially in the high-temperature activation zone. The heat source (such as flame, high-temperature flue gas, or electric heating element) not only directly radiates to the surface of the material bed but also to the refractory material on the inner wall. The heated kiln wall then transfers heat to the material through secondary radiation. At the same time, the convective heat transfer between the high-temperature airflow and the material, as well as the heat conduction within and between the material particles, together form a complete heat transfer network inside the furnace, ensuring efficient heat exchange.

(2)Core structural components: a precision system working in tandem.

The rotary activation furnace is a complex whole composed of multiple subsystems working in precise coordination, with each component serving to achieve a perfect activated carbon production process.

Rotary Cylinder: The core of the furnace. In activated carbon production, the activation temperature is typically as high as 850-1050°C, placing extremely high demands on the cylinder material. Externally heated furnaces often use heat-resistant stainless steel (such as 310S). Internally heated activation furnaces have high-alumina bricks, silicon carbide, or other refractory materials lined or cast into the inner wall of the cylinder to resist high temperatures and chemical corrosion.

Transmission Device: The power source driving the kiln’s rotation. Variable frequency speed-regulating motors are commonly used, allowing operators to flexibly adjust the speed and precisely control the material’s residence time within the furnace—a key method for controlling the activation depth.

Support Device: Bears the weight of the entire kiln and ensures its smooth rotation. Hydraulic thrust rollers counteract the axial thrust generated by the kiln’s tilt, ensuring stable equipment operation.

Sealing Device: Activated carbon production requires a strict atmosphere (carbonization requires an oxygen-deficient environment, activation requires a specific atmosphere), making sealing crucial. Modern designs employ multi-layered flexible seals such as graphite blocks and fish scales to effectively prevent external air leakage or internal gas escape, ensuring a pure and stable reaction environment.

Heating and Atmosphere System: This is the “heart” of the process. Internally heated furnaces inject fuel directly at the kiln head or tail, while externally heated furnaces are heated indirectly through an external heating hood. The system also includes precisely controlled injection lines for steam or other activators.

Feeding and Discharging System: The feeding system requires continuous and stable operation, often using a screw feeder. The discharge end needs a cooling device, such as a water-cooled screw conveyor, to rapidly cool the high-temperature activated carbon to room temperature, preventing oxidation upon contact with air and stabilizing product quality.

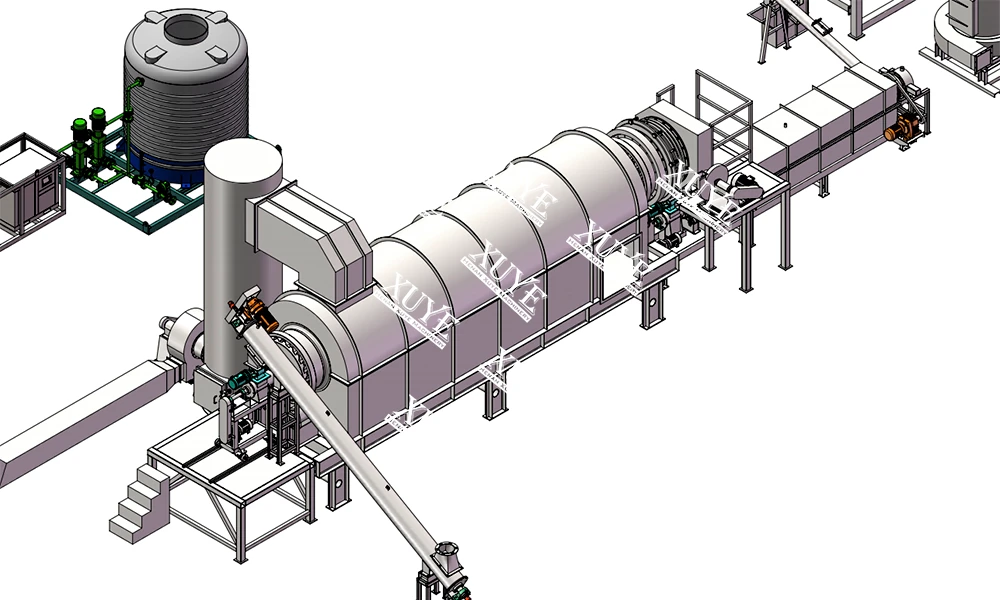

External heating activated carbon activation furnace

(3)Key Design and Operating Parameters: The Code to Regulating Product Performance

The final properties of activated carbon, such as iodine value and methylene blue value, are not accidental, but the result of a series of design and operating parameters that are precisely controlled.

| Parameter | Scope (activated carbon production) | Impact and role on activated carbon production |

| kiln body inclination angle | 1%-5% | The material’s forward speed is determined, and together with the rotational speed, the residence time is controlled. The tilt angle needs to be precisely designed to match the reaction time required for carbonization and activation. |

| Rotational speed | 0.5-5rpm | It affects the tumbling and mixing effect of materials. High rotation speed enhances heat transfer uniformity, but shortens residence time, requiring a trade-off between activation uniformity and activation depth. |

| Fill rate | 6%-36% | It affects production capacity and heat transfer efficiency. If the filling rate is too high, the central material will not be activated evenly; if it is too low, the equipment utilization rate will be insufficient. |

| Température | Carbonization: 400-650°C Activation: 850-1050°C | The core of process control. Segmented temperature control and precise maintenance of the temperature in each reaction zone are key to ensuring the pore size distribution and specific surface area of the product. |

2.Choosing a Technical Route – Internal Heating vs. External Heating in Activated Carbon Production

In the field of activated carbon production, choosing between an internally heated or externally heated rotary kiln is a strategic decision concerning product quality, production costs, and process flexibility. The two technical routes each have their own focus and are suitable for different product positioning and production needs.

(1)Externally Heated Rotary Kiln: Guarantee of High-Quality Activated Carbon

Core Advantages: Product Purity, Controllable Atmosphere

Externally heated rotary kilns use a “partitioned” heating system, completely isolating the heat source (combustion flue gas or electric heating elements) from the material inside the furnace. Heat is conducted to the material through the heat-resistant alloy cylinder wall. This design brings two unparalleled advantages:

- Unmatched Product Purity: Because the material does not come into contact with combustion products (such as smoke and sulfur oxides), product contamination is fundamentally avoided. This is crucial for producing high-purity activated carbon for use in food, pharmaceuticals, and drinking water purification.

- Precise Reaction Atmosphere Control: The furnace is an independent, sealed space, allowing for precise control of the concentration and flow rate of activators such as water vapor and carbon dioxide, while effectively eliminating interfering gases like oxygen. This precise control is a prerequisite for “sculpting” specific pore size distributions and achieving “directional preparation” of activated carbon.

Therefore, the externally heated rotary kiln is the preferred equipment for producing high-value-added, high-standard activated carbon (such as gold extraction carbon and supercapacitor carbon).

(2)Internal Heating Rotary Kiln: Cost-Effectiveness and the Choice for Large-Scale Production

Core Advantages: High thermal efficiency and low investment cost.

The internally heated rotary kiln injects fuel directly into the furnace, allowing high-temperature flue gas to directly contact the material for heat exchange. Its advantages are:

- Extremely High Thermal Efficiency: Shortest heat transfer path, minimal heat loss, and lower unit energy consumption, making it particularly suitable for large-scale production and effectively reducing production costs.

- Lower Equipment Investment: Relatively simple structure, eliminating the need for expensive external heating furnace chambers and heat-resistant alloy bodies (refractory lining is sufficient), making the initial investment more attractive.

However, the challenges are also quite obvious: the products are susceptible to flue gas contamination, and controlling the atmosphere inside the furnace is difficult. Nevertheless, by adopting advanced technologies such as secondary air supply and waste heat recovery, Xuye’s new internal heating activation furnace has made significant progress in product quality and energy consumption control, and is still widely used in the production of many general-purpose activated carbons.

Recommandations associées

-

Why can’t many manufacturers sell coconut shell carbonized materials at a high price?

4620Customized activated carbon kiln specifications according to customer needs, providing full technical solutions from laboratory-level small equipment to large production lines, supporting PLC automation control.

Voir les détails -

High-value regeneration of powdered waste activated carbon: Pathways for technological innovation and industrial upgrading

4766Customized activated carbon kiln specifications according to customer needs, providing full technical solutions from laboratory-level small equipment to large production lines, supporting PLC automation control.

Voir les détails -

High-value regeneration of powdered waste activated carbon: Pathways for technological innovation and industrial upgrading

4766Customized activated carbon kiln specifications according to customer needs, providing full technical solutions from laboratory-level small equipment to large production lines, supporting PLC automation control.

Voir les détails -

Ligne de production de charbon actif chimique

5516Comprendre l'équipement de la ligne de production de charbon actif chimique et la technologie de production professionnelle pour aider à améliorer la performance d'adsorption du charbon actif.

Voir les détails -

Applications du biochar : solutions durables pour les industries modernes

5606Le biochar est un matériau écologique produit par la pyrolyse de la biomasse qui peut améliorer la fertilité des sols, absorber les polluants et contribuer à la neutralité carbone.

Voir les détails -

Why can’t many manufacturers sell coconut shell carbonized materials at a high price?

4620Customized activated carbon kiln specifications according to customer needs, providing full technical solutions from laboratory-level small equipment to large production lines, supporting PLC automation control.

Voir les détails

Henan Xuye Machinery Equipment Co. Ltd.

Henan Xuye Machinery Equipment Co. Ltd.