Direct Heated Rotary Dryer

Single drum direct heated rotary dryer introduction

Direct heating dryer is a kind of equipment that dries materials through direct contact of heat energy. Its core features are high thermal efficiency and compact structure. It is widely used in large-scale material processing in industrial, agricultural and other fields.

The Single cylinder direct heated rotary dryer workflow consists of three main steps:

Heat source generation: High-temperature hot air is generated by burning fuel (such as coal, gas, or wood chips) or electric heating elements.

Direct contact drying: Hot air mixes directly with the wet material within a drum or chamber, rapidly evaporating moisture through convection and conduction. For example, in a drum dryer, the material is dispersed within the rotating drum by a lifting plate, ensuring full contact with the hot air.

Exhaust gas treatment: Wet exhaust gases are discharged via an induced draft fan. Some equipment is equipped with dust removal or purification devices to meet environmental requirements.

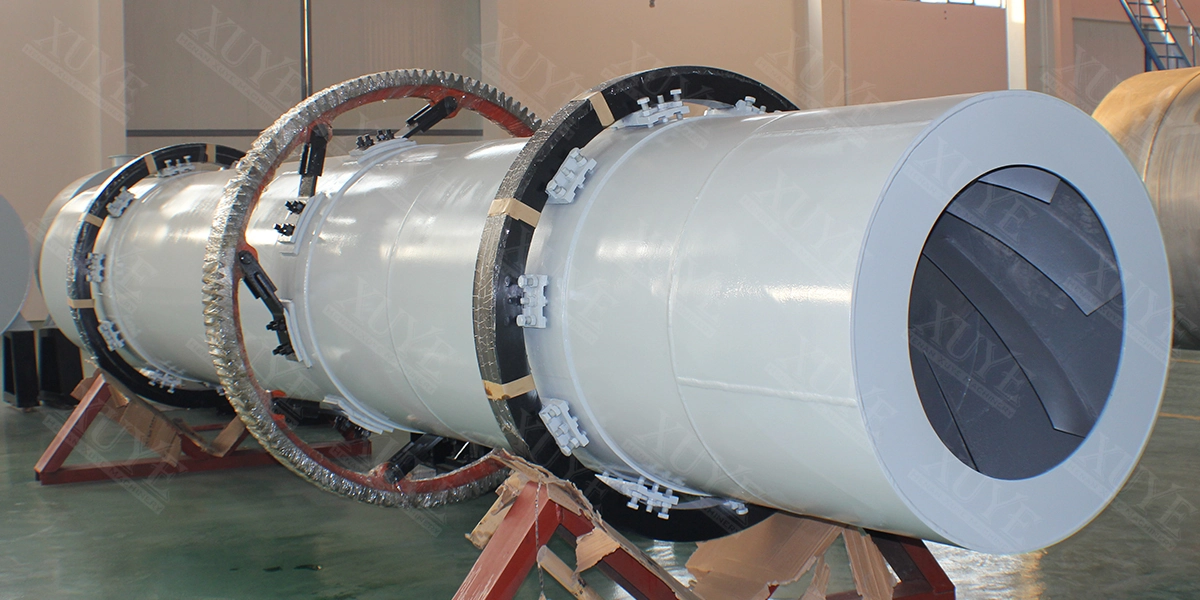

Single drum direct heated rotary dryer Key Structural Design

Drum-type core components: Taking the direct-heated drum dryer as an example, it primarily consists of a rotating body, a lifting plate, a transmission, and a sealing system. A self-aligning pulley structure reduces wear, and a retaining wheel design reduces horizontal thrust during tilted operation.

Multiple heat source compatibility: Hot air furnaces can be used with various fuels, including diesel, gas, coal, and straw. Some models also support electric heating, flexibly meeting energy supply needs in various scenarios.

Automated control system: Intelligently controlling feed rate, hot air temperature, and drum speed ensures stable drying quality. For example, electric heating models can precisely adjust the temperature to ensure even heating of the material.

Single drum direct heated rotary dryer video

Technical Parameters

| Model | Cylinder diameter(mm) | Cylinder length(mm) | Cylinder volume(m3) | Cylinder rotary speed (r/min) | Power(kW) | Weight(t) |

| 0.6×5.8 | 600 | 5800 | 1.7 | 1-8 | 3 | 2.9 |

| 0.8×8 | 800 | 8000 | 4 | 1-8 | 4 | 3.5 |

| 1×10 | 1000 | 10000 | 7.9 | 1-8 | 5.5 | 6.8 |

| 1.2×5.8 | 1200 | 5800 | 6.8 | 1-6 | 5.5 | 6.7 |

| 1.2×8 | 1200 | 8000 | 9 | 1-6 | 5.5 | 8.5 |

| 1.2×10 | 1200 | 10000 | 11 | 1-6 | 7.5 | 10.7 |

| 1.2×11.8 | 1200 | 11800 | 13 | 1-6 | 7.5 | 12.3 |

| 1.5×8 | 1500 | 8000 | 14 | 1-5 | 11 | 14.8 |

| 1.5×10 | 1500 | 10000 | 17.7 | 1-5 | 11 | 16 |

| 1.5×11.8 | 1500 | 11800 | 21 | 1-5 | 15 | 17.5 |

| 1.5×15 | 1500 | 15000 | 26.5 | 1-5 | 15 | 19.2 |

| 1.8×10 | 1800 | 10000 | 25.5 | 1-5 | 15 | 18.1 |

| 1.8×11.8 | 1800 | 11800 | 30 | 1-5 | 18.5 | 20.7 |

| 1.8×15 | 1800 | 15000 | 38 | 1-5 | 18.5 | 26.3 |

| 1.8×18 | 1800 | 18000 | 45.8 | 1-5 | 22 | 31.2 |

| 2×11.8 | 2000 | 11800 | 37 | 1-4 | 18.5 | 28.2 |

| 2×15 | 2000 | 15000 | 47 | 1-4 | 22 | 33.2 |

| 2×18 | 2000 | 18000 | 56.5 | 1-4 | 22 | 39.7 |

| 2×20 | 2000 | 20000 | 62.8 | 1-4 | 22 | 44.9 |

| 2.2×11.8 | 2200 | 11800 | 44.8 | 1-4 | 22 | 30.5 |

| 2.2×15 | 2200 | 15000 | 53 | 1-4 | 30 | 36.2 |

| 2.2×18 | 2200 | 18000 | 68 | 1-4 | 30 | 43.3 |

| 2.2×20 | 2200 | 20000 | 76 | 1-4 | 30 | 48.8 |

| 2.4×15 | 2400 | 15000 | 68 | 1-4 | 30 | 43.7 |

| 2.4×18 | 2400 | 18000 | 81 | 1-4 | 37 | 53 |

| 2.4×20 | 2400 | 20000 | 91 | 1-4 | 37 | 60.5 |

| 2.4×23.6 | 2400 | 23600 | 109 | 1-4 | 45 | 69.8 |

| 2.8×18 | 2800 | 18000 | 111 | 1-3 | 45 | 62 |

| 2.8×20 | 2800 | 20000 | 123 | 1-3 | 55 | 65 |

| 2.8×23.6 | 2800 | 23600 | 148 | 1-3 | 55 | 70 |

| 2.8×28 | 2800 | 28000 | 172 | 1-3 | 75 | 75 |

| 3×20 | 3000 | 20000 | 14 | 1-3 | 55 | 75 |

| 3×23.6 | 3000 | 23600 | 170 | 1-3 | 75 | 85 |

| 3×28 | 3000 | 28000 | 198 | 1-3 | 90 | 91 |

| 3.2×23.6 | 3200 | 23600 | 193 | 1-3 | 90 | 112 |

| 3.2×32 | 3200 | 32000 | 257 | 1-3 | 110 | 129 |

| 3.6×36 | 3600 | 36000 | 366 | 1-3 | 132 | 164 |

| 3.8×36 | 3800 | 36000 | 408 | 1-3 | 160 | 187 |

| 4×36 | 4000 | 36000 | 452 | 1-3 | 160 | 195 |

Henan Xuye Machinery Equipment Co., Ltd.

Henan Xuye Machinery Equipment Co., Ltd.